The advantages over the conventional spot repair

- Time saving: UV car paint repair uses a special UV lamp to dry the paint quickly. This eliminates the need to wait for long drying times, as is the case with conventional repairs. This results in significant time savings.

- Cost efficiency: since UV automotive paint repair is a faster method, there are fewer labor hours, resulting in lower repair costs. In addition, there is no need to occupy a paint booth, and the UV method can be used universally, regardless of location.

- Environmental friendliness: UV automotive paint repair generates less waste compared to traditional repair methods, which often use large amounts of paint and solvents. This makes it a more environmentally friendly option.

- Precision: UV automotive paint repair can target minor damage, such as scratches or stone chips, without having to repaint the entire paint area. This preserves the original color and finish of the vehicle, resulting in a more precise repair.

However, it is important to note that not all paint damage can be repaired with UV automotive paint repair. For more extensive damage or if the paint is severely damaged, a traditional repair method may be required.

How does UV drying work?

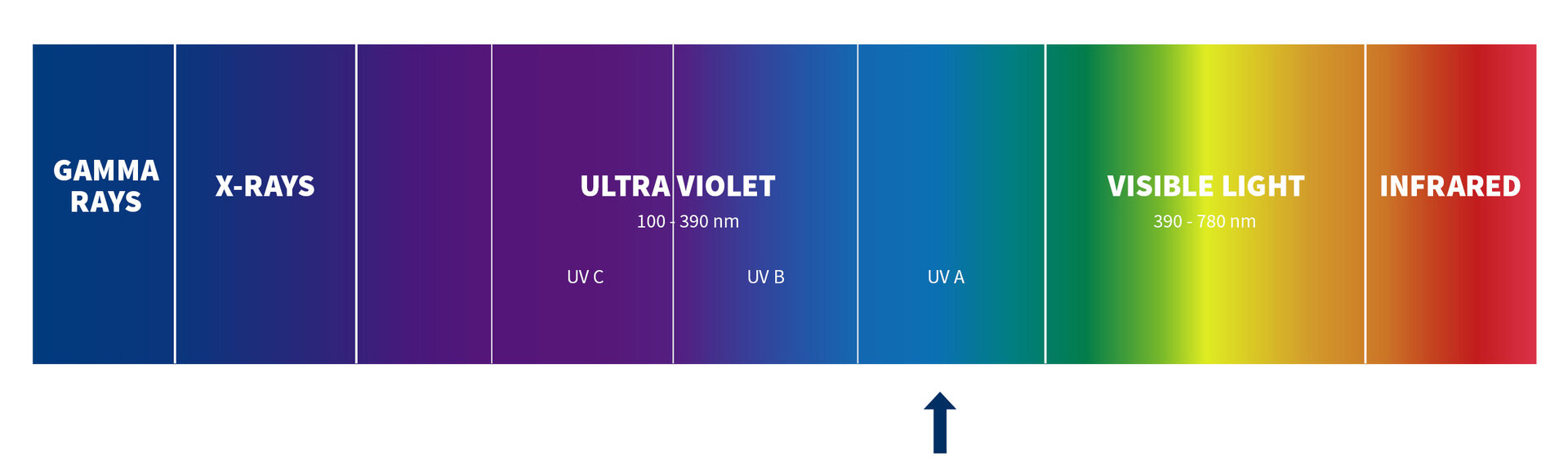

The decisive factors here are the so-called photoinitiators, chemical components of the UV coating. When activated by UV-A light, the curing process begins. UV coatings always require a UV lamp for drying. Sunlight alone does not usually provide the evenly dosed radiation necessary for uniform through-curing. Curing through depends on the wavelength and dose of the UV lamps.

How to get started with Spot Repair with UV

We offer you a compact 1-day practical training, our application technicians give you insights into the technology, required equipment and show you how the application works step by step. You will learn to assess which damages are suitable for the UV repair method and how to use it most economically for your company. You will perform UV Spot Repair yourself with the aerosol cans under guidance.