With a SprayMax® 2K aerosol you get

a professional result which is quality

and durability of the original paintwork.

The special SprayMax aerosol technology cannot be compared with conventional spray can technology. Only the optimum interaction of production know-how and aerosol technology, right down to the right combination of hardware (can, valve, spray nozzle, mixing ball), enable the unmistakable SprayMax aerosol technology and the associated system and user benefits.

With the spray gun, the compressed air comes from outside and hits the paint particles shortly after they escape through the gun nozzle. This immediately atomizes them and distributes them radially, resulting in heavy contamination of the surrounding area, which has to be cleaned again.

SprayMax sprays completely differently: the propellant is dissolved in the paint particles. After the paint particles have left the spray nozzle, the atomization process continues until the paint surface is reached. On the one hand, you have larger, heavier particles at the origin of the spray, which are therefore much more targeted at the surface to be painted. On the other hand, the continuous atomization produces a uniform painting result. In addition, you can see from the pictures that the SprayMax spray jet has much sharper edges than the spray gun, which illustrates that the paint particles are held together better and therefore there is much less overspray.

Variator spray nozzle

With the Variator spray nozzle, the spray jet direction and the spray jet size can be optimally adjusted to the damage location to be processed and the respective damage size easily and quickly:

The 1st component is the paint. Depending on the application, this can be a primer, a color coating, a top coat, a clear coat or special coatings. The 2nd component is the hardener. It ensures that the paint hardens after application, cross-links and thus becomes very hard and resistant. A 2K spray requires an additional working cut before you can use it:

The name SprayMax stands for professional applications with paints from the aerosol can. 2K stands for two components. They are stored separately from each other in the spray can. Directly before use, the activation of the spray can mixes the two components together, causing the desired chemical reaction after spraying. Only original coatings of the well-known manufacturers are used.

The 1st component is the paint. Depending on the application, it can be a primer, color paint, car top coat, clear coat or special paints.

The 2nd component is the hardener. It ensures that the paint hardens after application, cross-links and thus becomes very hard and resistant.

Shelf life

The spray can has a shelf life of several years. This only applies if the 2 components have not yet been mixed, i.e. the spray can has not yet been activated. As soon as it is activated, the lacquer and hardener are mixed together so that the chemical reaction starts, the cross-linking begins.

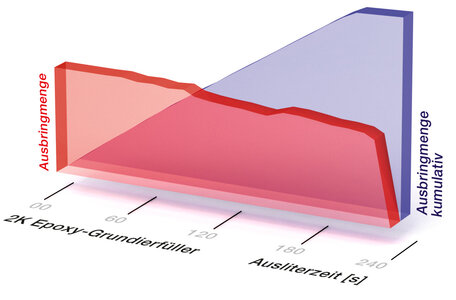

The hardening of the paint takes place not only on the painted surface, but also in the spray can. This happens in the can, however, much slower After 1-3 days, depending on the system used, that the paint in the spray can so far in the curing process that this is then no longer usable it How long exactly a 2K paint spray can after the release can be used, is indicated by pot types. Poti). There is precise information on this on the respective can and on the technical data sheet.

Drying time

The time required for surface or physical drying is comparable to conventional 1-component sprays. After as little as 20-30 minutes, the surface is grip-resistant and the coating is complete.

The cross-linking acion of the 2K system, however, takes longer, so that the desired property of the finished applied layer will set in the following 1-3 days. Therefore, after a repair coating, whether from an aerosol or a spray gun, it is not advisable to go to the car wash immediately. The paint is only fully scratch-resistant after 48-72 hours.

Only those with the red button

Not everywhere where 2K is on it, is also 2K in it!

We have tested SprayMax 2K clearcoat against a so-called 2K clearcoat without pot life: