2C Pot life

For 2C products, the additional information in hours or days indicates how long the product can be processed after the release, mixing of the hardness test. The information refers to a room temperature of 20-23°C. Higher room or storage temperatures shorten the pot life, lower temperatures extend the pot life. The pot life depends on the product, the filling material and the respective hardener/hardener ratio.

Sanding "dry" (machine / plate diameter)

For fast, homogeneous and dry sanding of the substrate. Additional information: Size of the sanding disc for better work on edges and curves as well as lower external rotation speed. Additional information Grit size indicates which grit size and sanding steps are recommended.

Drying "assembly-proof"

Drying level 5 according to DIN 53150. Additional information in minutes or hours. Indicates the time after which the processed object is ready for installation. The time is based on a room temperature of 20°C and the corresponding dry film thickness, see Technical Data Sheet.

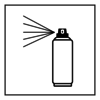

Adjust variator

Infinitely adjustable, variable spray head. The spraying direction can be adjusted horizontally or vertically. The spray pattern size can be continuously adjusted from maximum to minimum via the blue wheel on the spray head. Optimum application to the surface to be treated is possible. Cleaning either by turning the spray paint can upside down and briefly spraying the riser tube empty several times. Adjust the variator from max. to min. and spray or use the gun cleaner.

Storage stability

Indicates how long the product can be stored or used in an unopened or unsprayed state, or in the 2K range in an unreleased state. The service life refers to an unused aerosol can, stored properly between 15-25°C and a relative humidity not exceeding 60%. The aerosol can must be stored and transported in an upright position, dry and protected from chemical and mechanical influences.

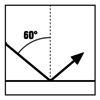

Gloss level "silk gloss / silk matt"

Measured gloss level at 60° measuring angle. Since the measurement figures vary depending on the substrate (paper, contrast card, lacquered cardboard, metal test sheet), the average value of the measurement is given in each case, as well as the corresponding bandwidth in units.

Clean spray head

For special valve: The usual cleaning of the spray head by turning the spray paint can upside down and spraying briefly does not technically work here. To avoid misplacement and clogging of the spray head, thoroughly wipe the front of the spray head and the spray channel outlet opening with a cloth or rag after use.

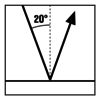

Gloss level "high gloss"

Measured gloss level at 20° measuring angle. As the measurement figures vary depending on the substrate (paper, contrast card, lacquered cardboard, metal test sheet), the average value of the measurement is given in each case, as well as the corresponding bandwidth in units.