1K Uni Zinc

500 ml | silver gray | Part-No.: 3680 601

Processing

1K UNI ZINC is particularly suitable as a corrosion protection for water and weather-resistant vulnerable constructions, for repairing damaged zinc surfaces and for coating inner panel edges during spot welding. The product can be used on heating systems, pipelines, steel structures, radiators, railings, crash barriers, etc.

Advantages

■ Corrosion protection for water and weather-prone structures

■ For repairing damaged zinc surfaces

■ For coating inner sheet metal edges spot welding

■ Applicable for heating systems, pipelines, steel superstructures, radiators, railings, crash barriers

■ Provides superior corrosion protection between welded substrates while minimizing heat affected zones and welding splatter

1K Uni Black

500 ml | satin black | Part-No.: 3680 602

Processing

1K topcoat for interior and exterior. For high-quality topcoat paint jobs and spot repairs on cars and motorcycles. Satin Black (27 -33 gloss Level until 60° measuring angle).

Avantages

■ Easy to use

■ High yield

■ Excellent coverage thanks to high solid content

■ Dries quickly

■ Very good flow

Processing

Fast-drying primer filler for the insulation of sanded-through areas with high filling power. Can be used directly on steel, galvanized steel, aluminum and various plastics.

Advantages

■ High filling power

■ Optimum stability

■ Good sandability

■ Good corrosion protection

■ Can be used on a wide variety of substrates.

Processing

1-component clearcoat for fast coating and sealing of repair and new paint jobs. Due to the good elasticity of the paint film, application is particularly recommended on soft, flexible components such as plastic parts.

Advantages

■ Easy application

■ Good drying

■ No color deviation

■ Good weather resistance with excellent UV protection

■ Very good flow

■ Very good polishability

Processing

SprayMax UNI Blend is the leader when it comes to blending. For homogeneous paint transitions in the spot coating area of 1K / 2K clear coats as well as 2K top coats with excellent spot coating results.

Advantages

■ Transition-free edge zones in the spot coating area

■ Excellent release properties

■ No color deviations

■ Can be polished without a tear-off edge.

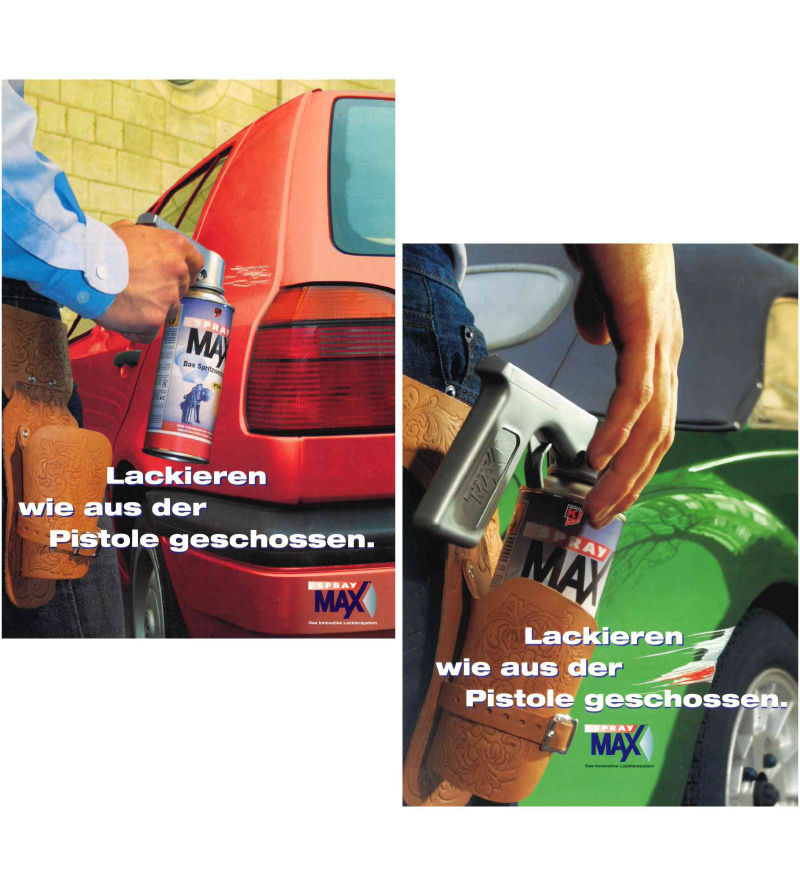

25 years of SprayMax technology

How the spray can conquered the painting industry

The year 1998 set a milestone in the history of Peter Kwasny GmbH. After successful years as a manufacturer of spray paint cans for hobbyists and do-it-yourselfers, the company succeeded in developing a can technology that could rival a professional spray gun in its spraying and application behavior. The SprayMax brand was born and with it an efficient solution for repair work in the paint store and in industry. Today, with a wide range of products, the brand is a technological leader and internationally successful.

The can as an economical alternative

Early on, entrepreneur and paint spray pioneer Peter Kwasny recognized the advantages of the handy and efficient can when it came to minor damage or rework, where using a spray gun is often expensive, cumbersome and ultimately uneconomical. However, the technical challenges were tough: fine atomization, good covering properties and, above all, constant spraying behavior until the can was emptied were the goals. Intensive research and development work followed until a new technology was finally presented in the form of SprayMax. At last, original paints could be applied more easily and flexibly than ever before, and many users, who were skeptical at first, were surprised by the quality. Since SprayMax only used paints from well-known brand manufacturers, the results were indistinguishable.

SprayMax soon convinced not only the body & paint stores, but also found its way into the industry. Today, numerous manufacturers from the automotive industry and other fields use the unique SprayMax technology for their applications and products.

SprayMax reloaded with varnish and hardener

The demand for 2-component lacquer then quickly developed, which once again presented the Kwasny developers with a major task. The task was to develop a can geometry that combines the lacquer and hardener ready for use in one product. The result was the 2K chamber system, which separates the components from one another and only allows them to react through a sophisticated triggering process. The now trademark "red button" that released the separating seals was invented and patented in 2000. . The product stability and thus the processing time of the activated 2K can are significantly improved compared to the liquid paint used, so that stress-free application is possible.

Into the can, ready, go

In order to meet the wishes and requirements of paint shops and workshops even better and to make working with SprayMax cans even more flexible, a filling system has been established in the form of FillClean, which further shortens the procurement process and preparation times. The cans, which are prefilled with coating ingredients, have been developed in such a way that only the respective basecoat needs to be mixed out and refilled. This means that a suitable quantity is available for painting at short notice, without the need for cumbersome retooling or cleaning of equipment.

Today, a SprayMax range is available that covers all products and work steps involved in repairing damage to paint and other painted automotive surfaces, so the user can work in a consistent, safe system. All the energy is already in the can, there is no need for any other power or heat consuming tools.

Export hit SprayMax: Back to the roots

And as the irony of history would have it: While Peter Kwasny brought the idea for the production of spray paint cans from North America to Gundelsheim on the Neckar 60 years ago, the company is now exporting cans back across the pond with resounding success. Peter Kwasny GmbH, now in the 2nd generation of family ownership, stands for these and many other brands and enjoys an excellent reputation, especially in the USA and Canada, due to the market success and popularity of SprayMax.

25 years are just the beginning

To mark the 25th anniversary, we are now honoring the tireless idea man and company founder Peter Kwasny with a SprayMax special series. The top-selling products of the "Edition PK" are presented in the popular 500 ml size, with 25% more content with a corresponding price advantage.

But 25 years is only the occasion for a gratifying interim conclusion. We have ambitious plans for the future of SprayMax: Modern coating systems are to be integrated and application performance improved even further. In view of the sustainability and environmental strategy to which we have committed ourselves holistically, all the components that make up SprayMax are being optimized for ecological improvements: the coating, the input materials and the recyclability of the materials used for the aerosol can, as well as production, transport and storage.